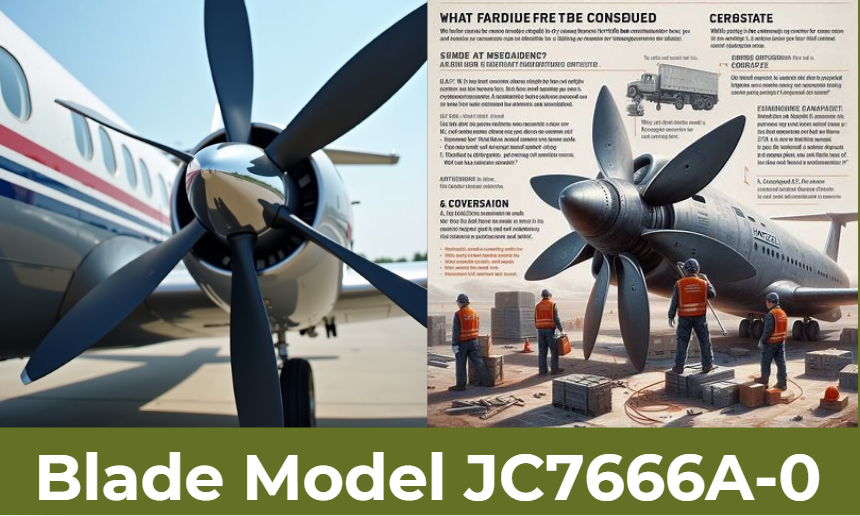

Ultimate Guide to the Blade Model JC7666A-0

The blade model JC7666A-0 is a highly specific aircraft propeller blade used in a variety of aviation applications. This guide will take you through its detailed specifications, applications, maintenance tips, and much more. Whether you’re a pilot, mechanic, or aviation enthusiast, understanding the ins and outs of this blade model will help ensure peak performance for your aircraft.

Introduction to the Blade Model JC7666A-0

The blade model JC7666A-0 is manufactured by Hartzell Propeller Inc. and is primarily used in aircraft propellers. This particular model is known for its efficient design, durability, and ability to handle various weather conditions. The blade is designed to pair with specific hub models like HC-C2YK-2LEU and HC-C2YK-2EU, which make it ideal for planes such as the Piper PA-34-200 Seneca.

This guide will dive deeper into its technical specifications, installation process, maintenance requirements, and more, ensuring that you can make the most of this aircraft component.

Specifications & Technical Details

Dimensions and Material Composition

The blade model JC7666A-0 features a sleek design, engineered to provide maximum aerodynamic efficiency. Typically, it’s made from high-strength materials that ensure durability and resistance to wear, even under the toughest operational conditions. The precise measurements of the blade include specific length, width, and pitch angles, tailored to optimize engine performance and aircraft stability.

Performance Ratings

This blade model is known for its balanced performance characteristics, including excellent torque absorption and efficient power transmission from the engine to the aircraft. Its aerodynamic design enhances fuel efficiency, contributing to reduced operational costs over time.

Compatibility

The blade model JC7666A-0 is mainly used with Hartzell propeller hub models such as HC-C2YK-2LEU, HC-C2YK-2EU, and other similar hubs. It’s important to use compatible hubs for optimal performance. The blade is specifically designed for twin-engine aircraft like the Piper PA-34-200 Seneca, enhancing both speed and fuel efficiency.

Key Features of the Blade Model JC7666A-0

- Designed for twin-engine aircraft

- Compatible with Hartzell hub models HC-C2YK-2LEU, HC-C2YK-2EU

- Manufactured with high-strength materials for durability

- Enhanced aerodynamic design for fuel efficiency

Applications & Aircraft Compatibility

The blade model JC7666A-0 is most commonly seen in twin-engine aircraft, particularly the Piper PA-34-200 Seneca, a popular model among light aircraft. The blade is part of a larger propeller assembly that helps optimize engine performance, making it an integral part of aircraft operation.

Aircraft Models Using the JC7666A-0

- Piper PA-34-200 Seneca

- Other compatible aircraft models include those using Hartzell hub configurations such as HC-C2YK-2LEU and HC-C2YK-2EU.

Enhancements in Aircraft Performance

When paired with the appropriate hub models, the blade model JC7666A-0 significantly boosts an aircraft’s overall performance. The blade’s design ensures smooth airflow, which contributes to better fuel efficiency, reduced noise, and enhanced stability. Whether you’re flying cross-country or engaging in short regional flights, this blade model provides reliable and efficient performance.

Manufacturing & Design Process

The blade model JC7666A-0 is produced by Hartzell Propeller Inc., a renowned manufacturer in the aviation industry. The production process is highly meticulous, involving advanced manufacturing techniques that ensure precision and quality control. Each blade undergoes extensive testing and inspection to meet FAA regulations and safety standards.

Production Steps

- Material Selection: High-grade materials are selected to withstand the high pressures and forces experienced during flight.

- Manufacturing: The blade is crafted using state-of-the-art equipment to ensure precise dimensions and aerodynamic properties.

- Testing and Inspection: Each blade undergoes rigorous testing to ensure it meets performance standards.

- Certification: The blade is certified by aviation authorities such as the FAA, ensuring it adheres to safety and operational standards.

Performance & Durability

One of the standout features of the blade model JC7666A-0 is its performance and longevity. Designed for high-efficiency operation, the blade’s aerodynamic design reduces drag and increases fuel efficiency. Furthermore, the materials used in its construction are resistant to wear, corrosion, and other environmental factors, making the blade ideal for use in diverse weather conditions.

Longevity and Maintenance

With proper care and regular maintenance, the blade model JC7666A-0 can last for thousands of flight hours. Regular inspections and adherence to recommended maintenance schedules are crucial to ensuring its continued performance and safety.

Installation & Replacement Guide

Installing or replacing the blade model JC7666A-0 requires knowledge of both aircraft and propeller systems. It’s essential to use the correct tools and follow a step-by-step process to ensure proper installation.

Steps for Installation

- Prepare the Aircraft: Secure the aircraft and ensure the engine is turned off.

- Remove the Old Blade: Carefully disconnect the old propeller blade, making sure to document any previous damage or wear.

- Attach the New Blade: Align the blade model JC7666A-0 with the hub and securely fasten it in place.

- Check for Tightness: Ensure the blade is tightly affixed and test it for any movement.

Maintenance, Repairs, & Safety Tips

Regular maintenance is key to ensuring the longevity and efficiency of the blade model JC7666A-0. Inspect the blade for any signs of wear, cracks, or damage. Cleaning the blade after each flight is also essential to remove debris and prevent corrosion.

Maintenance Schedule

- Every 100 flight hours: Inspect for cracks, wear, and general condition.

- Every 500 flight hours: Complete disassembly for thorough inspection.

Cost, Pricing, & Where to Buy

The blade model JC7666A-0 is available for purchase from several authorized dealers and aviation parts suppliers. Prices may vary depending on the vendor, condition (new or refurbished), and any warranties offered.

Average Price Range

- New blades typically range between $1,500 – $3,000 depending on the vendor and any additional services provided.

- Refurbished models can cost significantly less, with prices starting around $1,000.

You can find the blade model JC7666A-0 at authorized dealers like Texas Air Salvage and Hartzell Propeller.

Reviews & User Experiences

Pilots and aviation mechanics who have used the blade model JC7666A-0 frequently praise its reliability and efficiency. Many report significant improvements in fuel efficiency and overall aircraft performance after installation.

Industry Regulations & Certifications

The blade model JC7666A-0 is FAA-certified, ensuring that it complies with all necessary regulations for safe flight. It’s important for aircraft owners and maintenance professionals to adhere to these regulations to ensure safe and efficient operation.

FAQs for the Blade Model JC7666A-0

Yes, new blades should be carefully monitored during the first 10-20 flight hours. Regular inspections for proper alignment, bolt tightness, and performance adjustments ensure smooth integration with the aircraft’s propeller system.

What factors should be considered when storing the Blade Model JC7666A-0?

The blade should be stored in a dry, temperature-controlled environment to prevent corrosion and material degradation. Keeping it covered and away from direct sunlight or moisture will help maintain its integrity.

Can the Blade Model JC7666A-0 be customized for specific aircraft models?

While it is primarily designed for specific Hartzell hub configurations, some modifications may be possible with FAA-approved alterations or custom fittings by certified aviation mechanics.

How does altitude affect the performance of the Blade Model JC7666A-0?

Higher altitudes can impact engine efficiency and propeller performance due to thinner air density. This blade model is designed to optimize thrust, but adjustments in pitch settings may be needed for optimal results in different flight conditions.

What are the common signs of imbalance in the Blade Model JC7666A-0?

Unusual vibrations, increased noise levels, and uneven wear patterns on the blade surface can indicate imbalance, which should be addressed immediately to avoid further damage to the propeller assembly.

Is there a recommended break-in period after installing a new JC7666A-0 blade?

Conclusion: Summary of the Blade Model JC7666A-0

The blade model JC7666A-0 stands out as a top choice for twin-engine aircraft due to its superior aerodynamic properties, durability, and fuel efficiency. With proper installation and maintenance, it provides optimal performance, reducing operational costs and enhancing flight safety. Whether you’re a mechanic, pilot, or aircraft owner, understanding the detailed aspects of this blade will help ensure it performs at its best for years to come.

By following the guidelines in this comprehensive guide, you’ll ensure the longevity and efficiency of your blade model JC7666A-0, making it a trusted component for many aviation professionals.

Read more

Alpha Size L Men’s COOGI Longreef Zip Hoody – A Complete Guide

Enchanted Disney Rapunzel Rose de 1.25 Carat Amethyst: A Magical Jewelry Masterpiece

The Ultimate Guide to Payday Loans eLoanWarehouse

How to Make Your First Million: The Ultimate Guide by make1m.com

The Ultimate Guide to Emails Info ClearSkinStudy – Everything You Need to Know